3D printing technology has ushered in a new era of innovation, empowering designers and engineers to push the boundaries of what is possible.

The Benefits of 3D Printing in Prototyping

In the dynamic landscape of product development and innovation, 3D printing (a.k.a. additive manufacturing) has emerged as a revolutionary technology, particularly in the realm of prototyping. The ability to create tangible three-dimensional objects from digital designs has fundamentally changed the way designers, engineers, and manufacturers approach the prototyping phase.

3D printing allows for the rapid iteration of designs. Designers can quickly modify and refine prototypes, speeding up the overall product development timeline.

Traditional prototyping methods can potentially be expensive, especially when creating molds or tooling for small production runs. 3D printing eliminates the need for these costly intermediate steps. It offers a cost-effective solution for producing prototypes directly from digital files, reducing material waste and associated expenses.

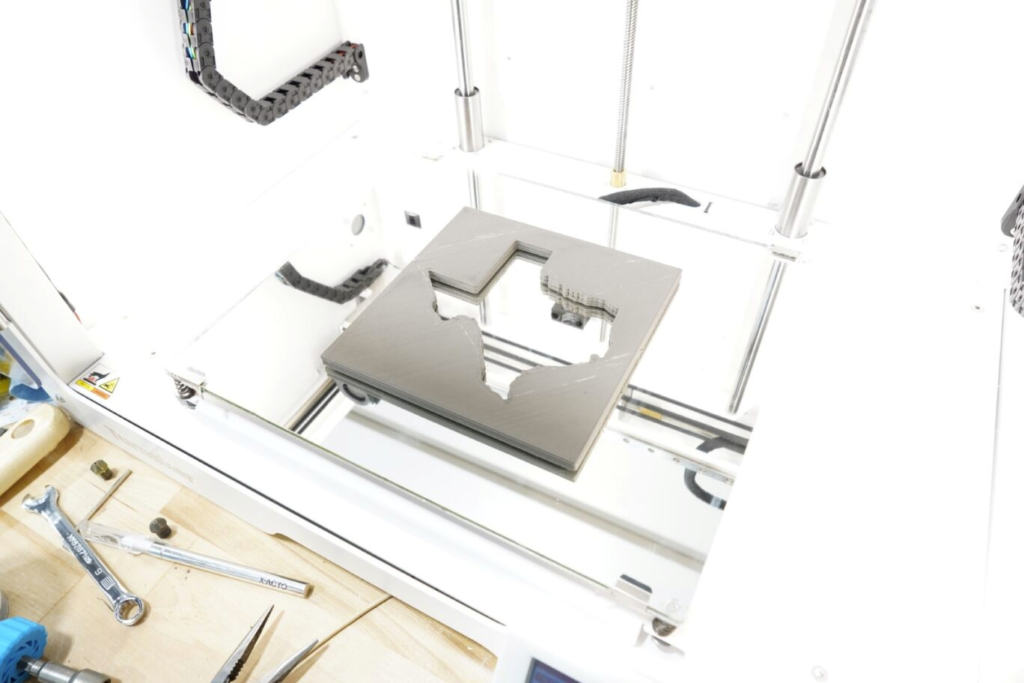

One of the standout advantages of 3D printing is its ability to fabricate complex geometries and intricate designs that would be challenging or impossible with traditional methods, such as injection molding. This allows designers to explore and test unconventional shapes and structures in their prototypes.

One of the most popular types of 3D printing, Fused Deposition Modeling (FDM), empowers designers to create highly customized and personalized prototypes by extruding thermoplastic materials layer by layer through a heated nozzle to create the final object. Filament and Pellet printers are the most common FDM printers in use today. Pellet printers offer a unique opportunity to print parts using many different types of commodity resins, engineering resins, and composite materials. They also eliminate the need and cost to process materials into a filament prior to printing.

By accelerating the prototyping phase and enabling rapid design changes, 3D printing contributes to a reduced time to market. Companies can respond more quickly to market demands, stay ahead of competitors, and bring innovative products to consumers in a shorter timeframe.

Prototyping is a crucial step in identifying and addressing potential issues before mass production. 3D printing allows for the identification of design flaws or improvements in the early stages, minimizing risks associated with expensive tooling or manufacturing errors.

The benefits of 3D printing for prototyping extend beyond mere efficiency gains. The technology has ushered in a new era of innovation, empowering designers and engineers to push the boundaries of what is possible. As 3D printing continues to evolve, its impact on prototyping will likely play a pivotal role in shaping the future of product development across various industries.

Contact us today, or fill out our RFQ form to see how we can help with your 3D Printing project.