The answer to this question seems easy if one assumes, as we have for years, that ammunition is simply expendable. Very few military planners thought there would be follow-on costs associated with each round fired. Rather, we assumed that once the trigger was pulled, the money was spent — case closed. Unfortunately, bullets in the 21st century are not as expendable as we once believed. In fact, years later they still have a clean-up cost associated with them due to the projectile’s high lead content and potential impact on the environment. Green ammunition has been developed to reduce the need for clean-up and with it, the overall true life-cycle cost of a bullet. This green ammo also characterizes the Army’s greater commitment to its stewardship of the environment

Several years ago, a joint working group (JWG) was formed to investigate and solve the environmental problems associated with the manufacture and use of small caliber service rounds. Chaired by the Small Caliber Ammunition Group at the U.S. Army Armament Research, Development and Engineering Center (ARDEC), efforts to develop and implement solutions have been coordinated between the Department of Defense, Department of Energy and law enforcement agencies. With the backing of the JWG, the ARDEC and the U.S. Army Environmental Center partnered to find substitutes for lead in small caliber bullets.

The U.S. Army Environmental Center is funding efforts at ARDEC to develop lead-free projectiles for 5.56 mm, 7.62 mm, 9 mm and .50-caliber standard service ammunition. Tungsten — a resilient metal used in light bulbs and cutting tools — was selected to replace lead. Tungsten has low toxicity and data indicates that it is environmentally benign. Suitable for combat, tungsten composite bullets pose no risk of lead contamination and will reduce environmental compliance burdens on many small arms ranges. The tungsten composite bullets match or exceed performance requirements for function, accuracy, lethality and penetration.

The 5.56 mm ball qualification testing is complete. An engineering change proposal (ECP) for the new production design has been approved, and lead-free 5.56 mm projectiles are currently under production. Initially, the cost of the 5.56 mm round will increase by 11 cents, but efficiencies should reduce this significantly as production ramps up. Efforts are well under way to produce tungsten 5.56 mm tracer, 7.62 mm ball and tracer, 9 mm ball and .50-caliber ball ammunition. The new bullets will eliminate the need for repetitive, costly cleanup.

Standard Army firing ranges are designed in accordance with TC 25-8, Training Ranges. At a smaller Army installation, a typical battle sight zero range for the M16A2 rifle might have 50 lanes or firing positions with a target berm situated approximately 30 meters from the firing line. The typical impact berm may be constructed of a sand-clay mixture of earth pushed into a small backstop hill 10 meters high and spanning the entire width of the range, about 200 meters.

It is reasonable to assume that cleaning up lead from this particular range may require excavating the top meter of soil and thus a total of 3,636 tons of earth. Clearly, lead accumulations can become an enormous burden, and range managers must be prepared for eventual lead removal, either as normal maintenance or cleanup.

The cost of removing lead from ranges varies depending on the method used and site conditions. Mining industry technologies such as dry screening, wet screening and acid washing have been shown to be effective in removing lead from range soils and allowing for recycling of the lead. Dry screening costs about $30 per ton of soil, but only recovers between 50 percent and 75 percent of the lead. Wet screening costs from $40 to $60 per ton of range soil and recovers 74 percent to 95 percent of the lead. Acid washing costs about $170 per ton and has a 95 percent recovery rate. A method of last resort is the removal of both the lead and the soil without separating the lead, which means the soil will have to be disposed of as a hazardous waste. This method has no recycling capability, can cost up to $200 per ton and is the least preferred method. Regardless of the method, a treatability study on the range site is required to determine the most suitable technology. Each method described has limitations that are governed not only by local regulations but also by the physical characteristics of the local soil.

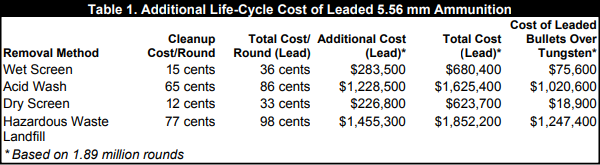

The current market cost of a leaded 5.56 mm round is 21 cents compared to 32 cents for a lead-free tungsten composite round. Using our typical range scenario, we can estimate both the number of bullets (1.89 million) and the cost of lead removal — 3,636 tons times cost/ton (column 3). This makes it possible to calculate the recovery cost per bullet (column 1) and thus compare the true life-cycle cost of a leaded 5.56 mm ball bullet (column 2) to the lead-free tungsten bullet (32¢). In the final column we calculated the cost savings if we had fired all green ammo for ten years instead of leaded bullets.

By comparing the total cost for each bullet, it is clear that in every case the green ammunition is cheaper throughout the life cycle of the round. The cost differences shown are obviously estimates and there are many other factors that may increase or decrease these costs. The costs presented in the chart do not include the additional costs that could be associated with environmental studies, mission impacts from closed ranges or unusually extensive cleanups, if required. Few planners could have estimated years ago that a typical lead bullet could cost so much after it was expended.

COL. STANLEY LILLIE is the commander of the U.S. Army Environmental Center, Aberdeen Proving Grounds, Md. MAJ. MARK T. CORBETT was an action officer assigned to the U.S. Army Environmental Center. He is now assigned to the Inspector General’s Office of HQ, Training and Doctrine Command. RICK O’DONNELL works in the Technology Implementation Branch of USAEC’s Pollution Prevention/Compliance, Acquisition Technology Division.

Copyright © 2004 by The Association of the U.S. Army